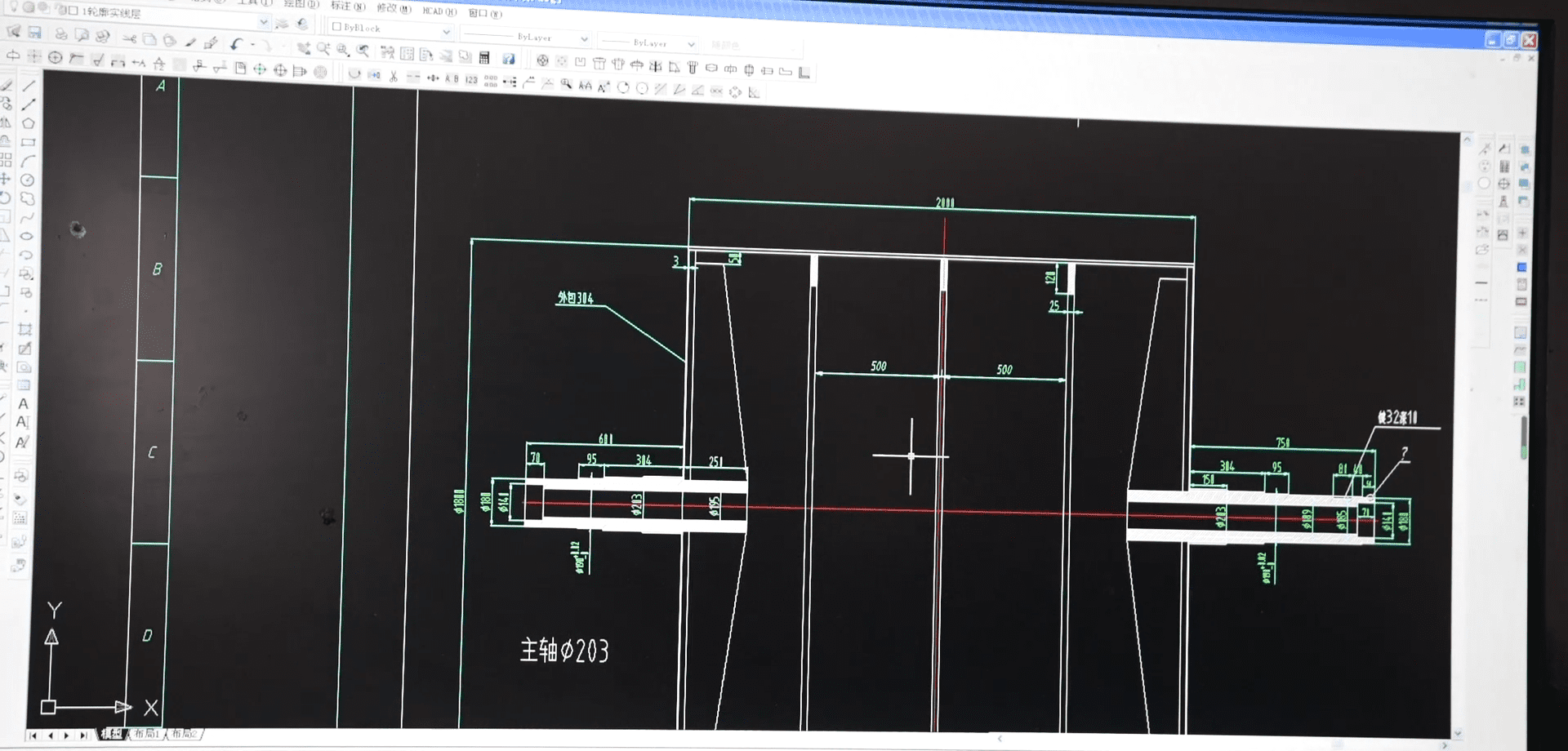

Non detachable (Type I) spiral plate heat exchanger

Heat Exchanger

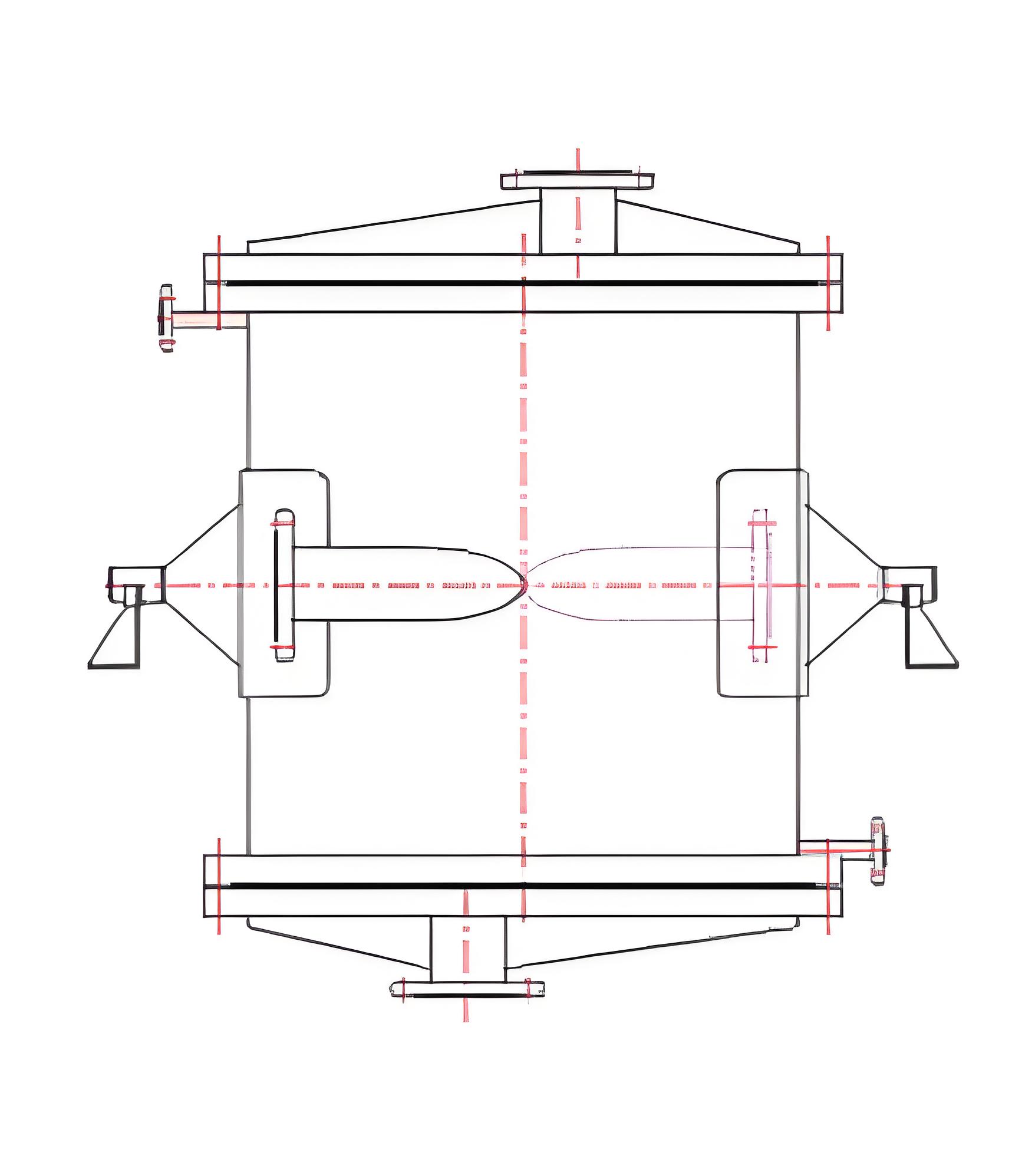

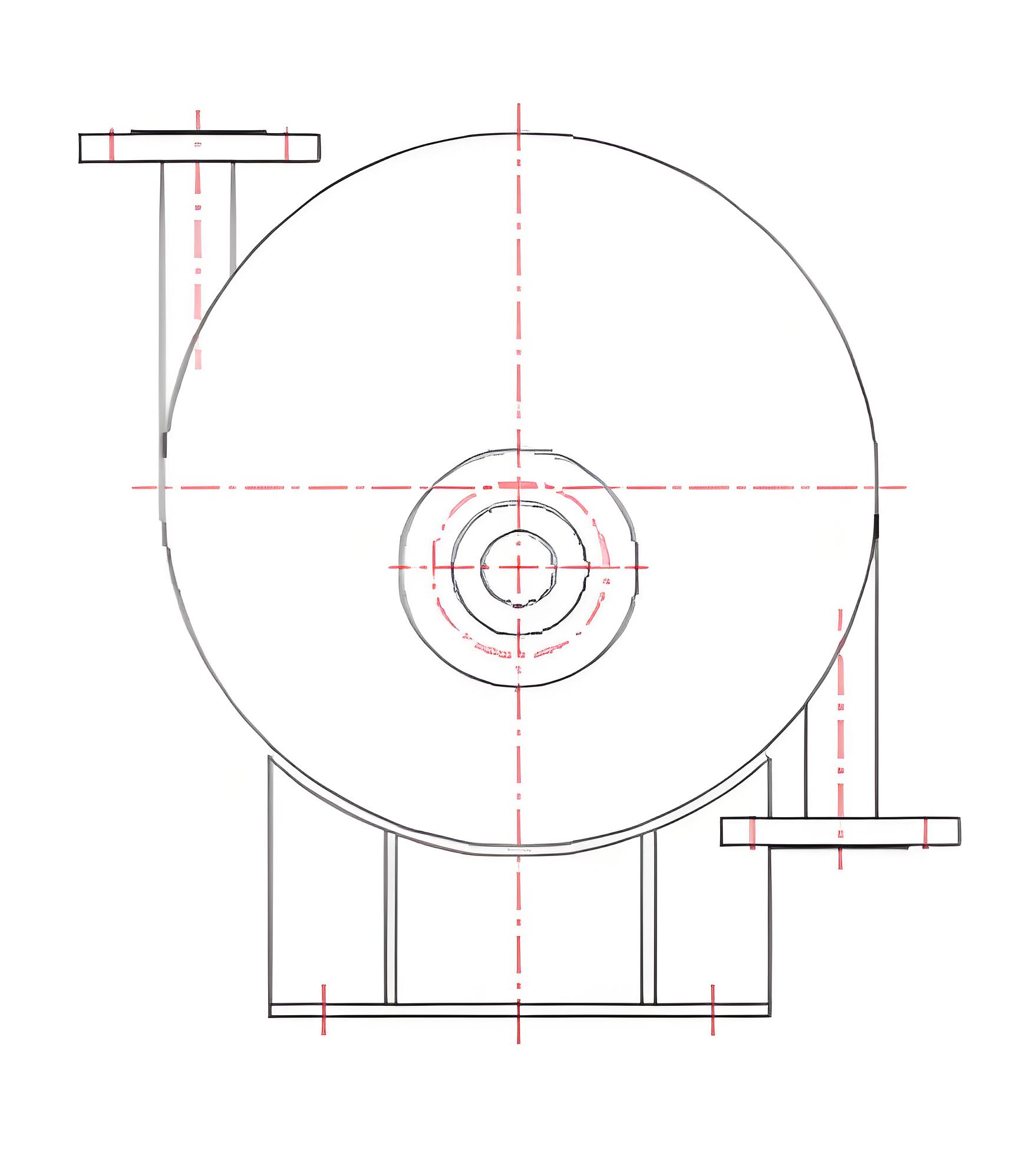

Spiral Heat Exchanger consists of two long flat plates wrapped around a center, creating two concentric spiral channels. The hot and cold fluid channel into the spiral heat exchanger counter-current to maximize heat transfer. The velocity of the fluid increases when there’s a deposit in the spiral heat exchanger which will cause scrubbing effect that removes the deposits.

Spiral plate heat exchanger is an efficient heat exchange equipment, suitable for gas air, gas-liquid, liquid-liquid, as well as for condensation and liquid evaporation heat transfer. This product has the advantages of high heat transfer efficiency, strong self-cleaning ability for dirt, good energy-saving effect, small size, low price, and reliable use. The product is widely used in industries such as chemistry, petroleum, solvents, pharmaceuticals, food, light industry, textiles, metallurgy, steel rolling, coking, etc. According to the structural form, it can be divided into non detachable (Type I) spiral plate heat exchangers and detachable (Type II, Type III) spiral plate heat exchangers.

How Does a Spiral Heat Exchanger Work?

Spiral Heat Exchanger consists of two long flat plates wrapped around a center, creating two concentric spiral channels. The hot and cold fluid channel into the spiral heat exchanger counter-current to maximize heat transfer. The velocity of the fluid increases when there’s a deposit in the spiral heat exchanger which will cause scrubbing effect that removes the deposits.

- Self-cleaning ability, due to its rotary current flow, fouling can be removed.

- High overall heat transfer coefficient.

- Very low maintenance and operating cost.

- Customizable based on specification needed.

- The nominal pressure PN of the spiral plate heat exchanger is specified as 0.6, 1, 1.6, and 2.5 MPa (i.e. the original 6, 10, 16, and 25 kg/cm) (referring to the maximum working pressure of a single channel). The test pressure is 1.25 times the working pressure.

- The material of the contact part between the spiral plate heat exchanger and the medium is Q235A and Q235B carbon steel, and SUS321, SUS304, and 3161 stainless steel acid port. Other materials can be selected according to user requirements.

- Allowable working temperature: t=0-+350 ℃ for carbon steel. Stainless steel acid steel has a temperature range of t=-40-500 ℃. According to the relevant regulations of pressure vessels, when selecting this equipment, appropriate process calculations should be carried out to ensure that the fluid in the equipment channel reaches a turbulent state. (Generally, the liquid flow rate is 1m/Sec and the gas flow rate is 10m/Sec) The equipment can be placed horizontally or vertically, but when used for steam condensation, it can only be placed vertically; Integrated heat treatment is necessary for the caustic soda industry to eliminate stress.

- When selecting equipment, appropriate process calculations should be carried out to ensure that the liquid in the equipment channel reaches a turbulent state (generally liquid velocity ≥ 0.5m/s; gas velocity ≥ 10m/s).

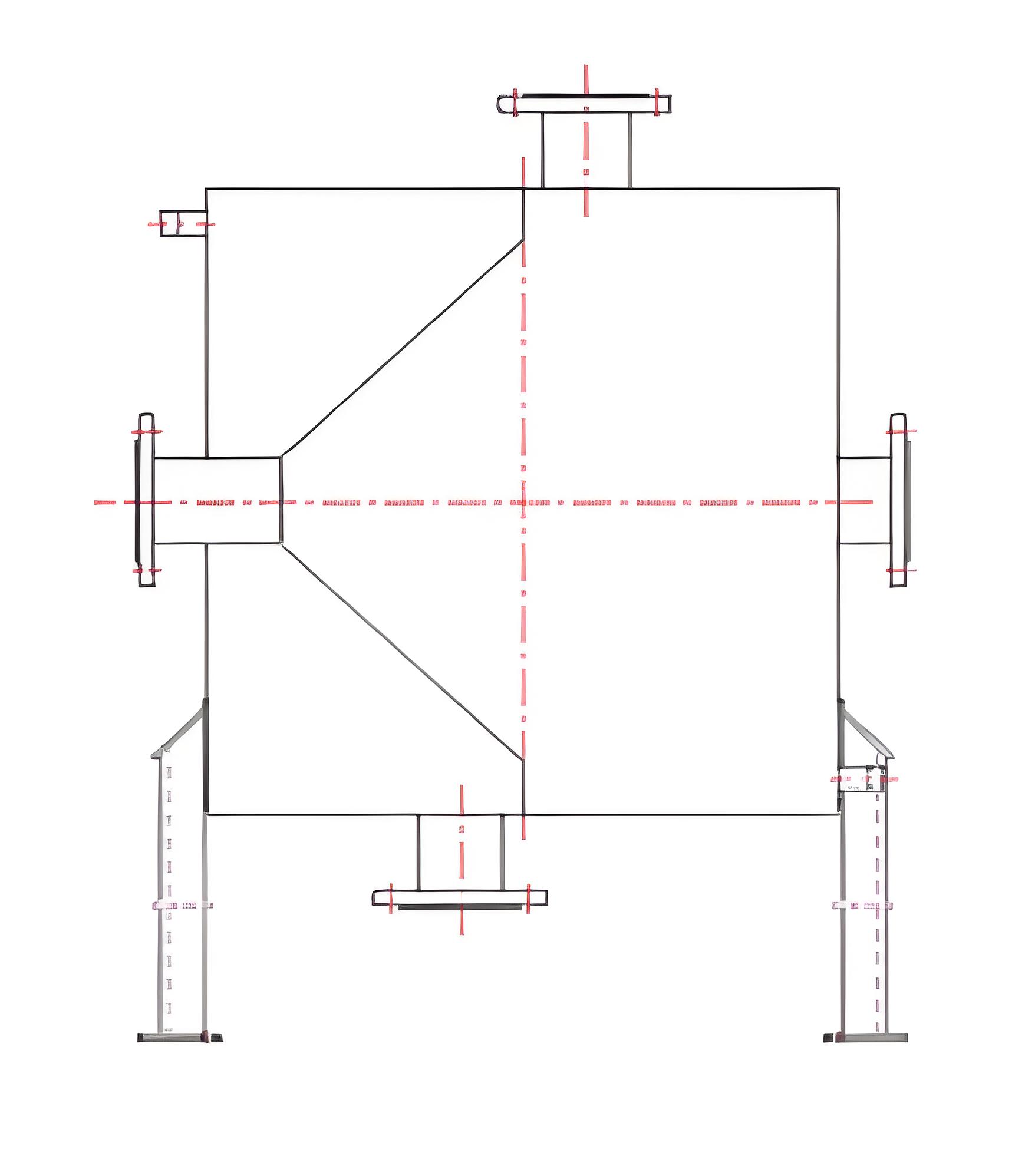

- The equipment can be placed horizontally or vertically, but it can only be placed vertically when used for steam condensation.

- For use in the caustic soda industry, overall heat treatment must be carried out to eliminate stress.

- When there is a significant difference in flow values between the two sides of the channel, unequal spacing channels can be used to optimize the process design.

hanging type

vertical

horizontal

Technical parameters of spiral plate heat exchanger

| Nominal heat exchange area | Channel spacing | carbon steel | stainless steel |

|---|---|---|---|

| Plate thickness | |||

| 5m² | 6=10 | 4mm | 2~3mm |

| 10m² | 6-10 | 4mm | 2~3mm |

| 20m² | 6-14 | 4mm | 2~3mm |

| 30m² | 10-14 | 4mm | 2~3mm |

| 40m² | 10-14 | 4mm | 2~3mm |

| 50m² | 10-14 | 4mm | 2~3mm |

| 60m² | 14-18 | 4mm | 2~3mm |

| 70㎡ | 14-18 | 4mm | 2~3mm |

| 80m² | 14-18 | 4mm | 2~3mm |

| 100m² | 14-18 | 4mm | 2~3mm |

| 120m² | 14-20 | 4~5mm | 2~4mm |

| 130m² | 14-20 | 4~5mm | 2~4mm |

Stainless acid resistant steel PN0.6, 1.6MPa non detachable (Type I) spiral plate heat exchanger

| Nominal heat exchange area ㎡ | Channel spacing mm | Calculate heat exchange area ㎡ | Current Speed 1m/ces hour Processing capacity m³/h | Take over nominal diameter | Model | Weight (kg) | |

|---|---|---|---|---|---|---|---|

| Type l 6B | Type l 16B | ||||||

| 1 | 6 | 1.0 | 3.89 | 40 | 16, I 16B1-0.2/300-6 | 44 | 50 |

| 2 | 6 | 2.1 | 3.89 | 40 | 16, I 16B2-02/400-6 | 78 | 85 |

| 4 | 6 | 4.4 | 8.2 | 50 | I 6, I 16B4-0.4/400-6 | 131 | 135 |

| 10 | 4.5 | 17.3 | 80 | I 6, I 16B4-0.5/450-10 | 129 | 133 | |

| 10 | 4.8 | 13.7 | 70 | I 6, I 16B4-0.4/500-10 | 161 | 205 | |

| 8 | 6 | 7.3 | 8.21 | 50 | I 6, I 16B8-0.4/500-6 | 212 | 215 |

| 10 | 7.85 | 17.3 | 80 | I 6, I 16B8-0.5/550-10 | 235 | 273 | |

| 10 | 7.3 | 20.90 | 80 | I 6, I 16B8-0.6/550-10 | 237 | 275 | |

| 10 | 6 | 11.1 | 8.21 | 50 | I 6, I 16B10-0.4/600-6 | 295 | 355 |

| 10 | 11.5 | 17.3 | 80 | I 6, I 16B10-0.5/650-10 | 315 | 405 | |

| 10 | 11.2 | 20.90 | 80 | I 6, I 16B10-0.6/600-10 | 305 | 395 | |

| 15 | 6 | 16.9 | 12.54 | 70 | I 6, I 16B15-0.6/600-6 | 415 | 490 |

| 10 | 14.72 | 17.3 | 80 | I 6, I 16B15-0.5/760-10 | 405 | 575 | |

| 10 | 15.0 | 28.1 | 80 | I 6, I 16B15-0.8/600-10 | 400 | 570 | |

| 14 | 15.6 | 39.3 | 100 | I 6, I 16B15-0.8/700-14 | 505 | 680 | |

| 20 | 6 | 21.7 | 8.21 | 50 | I 6, I 16B20-0.4/800-6 | 540 | 710 |

| 10 | 21.0 | 20.90 | 80 | I 6, I 16B20-0.6/800-10 | 555 | 735 | |

| 14 | 20.9 | 39.30 | 100 | I 6, I 16B20-0.8/800-14 | 660 | 830 | |

| 25 | 10 | 26.6 | 29.90 | 80 | I 6, I 16B25-0.6/900-10 | 610 | 950 |

| 14 | 26.9 | 39.20 | 100 | I 6, I 16B25-0.8/900-14 | 720 | 1060 | |

| 30 | 10 | 28.2 | 28.10 | 100 | I 6, I 16B30-0.8/800-14 | 750 | 1180 |

| 14 | 32.2 | 39.20 | 100 | I 6, I 16B30-0.8/1000-14 | 980 | 1370 | |

| 40 | 10 | 45.4 | 35.30 | 100 | I 6, I 16B40-1.0/900-10 | 1130 | 1515 |

| 14 | 40.2 | 19.4 | 125 | I 6, I 16B40-1.0/1000-14 | 1200 | 1630 | |

| 50 | 10 | 53.9 | 35.3 | 100 | I 6, I 16B50-1.0/1100-14 | 1360 | 1755 |

| 60 | 10 | 61.05 | 35.3 | 100 | I 6, I 16B60-1.0/1100-10 | 1920 | 2112 |

| 14 | 60.08 | 49.40 | 125 | I 6, I 16B60-1.0/1200-14 | 2000 | 2200 | |

| 80 | 10 | 81.83 | 35.3 | 100 | I 6, I 16B80-1.0/1200-10 | 2560 | 2816 |

| 14 | 80.9 | 49.40 | 125 | I 6, I 16B80-1.0/1400-14 | 2667 | 1934 | |

| 100 | 10 | 101.9 | 35.3 | 100 | I 6, I 16B100-1.0/1300-10 | 3200 | 3520 |

| 14 | 100.06 | 49.40 | 125 | I 6, I 16B100-1.0/1500-14 | 3333 | 3666 | |

| 120 | 10 | 115.5 | 35.3 | 100 | I 6, I 16B120-1.0/1500-10 | 3870 | 4257 |

| 14 | 119.0 | 49.40 | 125 | I 6, I 16B120-1.0/1700-14 | 4020 | 4422 | |

| 130 | 14 | 128.80 | 49.4 | 125 | I 6, I 16B130-1.0/1750-14 | 4241 | 4665 |

| 18 | 129.09 | 63.5 | 150 | I 6, I 16B130-1.0/1967-18 | 4462 | 4908 | |

| 150 | 14 | 148.1 | 49.4 | 125 | I 6, I 16B150-1.0/1890-14 | 4702 | 5172 |

| 18 | 148.2 | 63.5 | 150 | I 6, I 16B150-1.0/2010-18 | 4962 | 5458 | |

Carbon steel pg6, 16kg/non detachable (Type I) spiral plate heat exchanger

| Nominal heat exchange area ㎡ | Channel spacing mm | Calculate heat exchange area ㎡ | Current Speed 1m/ces hour Processing capacity m³/h | Take over nominal diameter | Model | Weight (kg) | |

|---|---|---|---|---|---|---|---|

| Type l 6T | Type l 16T | ||||||

| 6 | 6 | 6.50 | 8.20 | 50 | I 6, I 16T6-0.4/500-6 | 230 | 280 |

| 10 | 5.80 | 13.70 | 70 | I 6, I 16T6-0.4/600-10 | 285 | 350 | |

| 8 | 6 | 8.70 | 8.20 | 50 | I 6, I 16T8-0.4/600-6 | 370 | 430 |

| 10 | 7.70 | 17.30 | 80 | I 6, I 16T8-0.5/660-10 | 395 | 454 | |

| 10 | 8.70 | 13.70 | 70 | I 6, I 16T8-0.4/700-10 | 405 | 465 | |

| 10 | 6 | 9.90 | 12.50 | 70 | I 6, I 16T10-0.6/500-6 | 335 | 395 |

| 10 | 9.20 | 17.30 | 80 | I 6, I 16T10-0.5/660-10 | 472 | 543 | |

| 10 | 8.80 | 20.90 | 80 | I 6, I 16T10-0.6/600-10 | 410 | 495 | |

| 15 | 6 | 12.50 | 8.20 | 50 | I 6, I 16T15-0.4/700-6 | 510 | 580 |

| 10 | 14.64 | 17.30 | 80 | I 6, I 16T15-05/800-10 | 679 | 781 | |

| 10 | 13.30 | 20.90 | 80 | I 6, I 16T15-0.6/700-10 | 575 | 680 | |

| 14 | 13.80 | 29.20 | 100 | I 6, I 16T15-0.6/800-14 | 640 | 755 | |

| 20 | 6 | 19.00 | 12.50 | 70 | I 6, I 16T20-0.6/700-6 | 730 | 845 |

| 10 | 18.30 | 28.10 | 80 | I 6, I 16T20-0.8/800-10 | 735 | 870 | |

| 14 | 18.50 | 39.30 | 100 | I 6, I 16T20-0.8/800-14 | 810 | 960 | |

| 25 | 10 | 23.10 | 28.10 | 100 | I 6, I 16T25-0.8/800-10 | 935 | 1120 |

| 14 | 23.30 | 49.40 | 125 | I 6, I 16T25-1.0/800-14 | 1000 | 11 65 | |

| 30 | 10 | 29.00 | 35.30 | 100 | I 6, I 16T30-1.0/800-10 | 1190 | 1470 |

| 14 | 28.10 | 59 40 | 125 | I 6, I 16T30-1.2/800-14 | 1170 | 1425 | |

| 40 | 10 | 40.90 | 20.90 | 80 | I 6, I 16T40-0.6/1200-10 | 1725 | 1 885 |

| 14 | 42.30 | 39.30 | 100 | I 6, I 16T40-0.8/1200-14 | 1845 | 2110 | |

| 18 | 44.90 | 63.50 | 150 | I 6, I 16T40-1.0/1200-18 | 2075 | 2405 | |

| 50 | 10 | 46.20 | 35.50 | 100 | I 6, I 16T50-1.0/1000-10 | 1800 | 2085 |

| 14 | 53.20 | 49.40 | 125 | I 6, I 16T50-1.0/1200-14 | 2490 | 2595 | |

| 18 | 54.00 | 76.30 | 150 | I 6, I 16T50-1.2/1200-18 | 2435 | 2820 | |

| 60 | 10 | 56.80 | 20.90 | 80 | I 6, I 16T60-0.6/1400-10 | 2330 | 2635 |

| 14 | 60.70 | 39.30 | 100 | I 6, I 16T60-0.8/1400-14 | 2595 | 2850 | |

| 18 | 59.60 | 63.50 | 150 | I 6, I 16T60-1.0/1400-18 | 2730 | 3150 | |

| 80 | 10 | 76.40 | 28.10 | 100 | I 6, I 16T80-0.8/1400-10 | 2970 | 4060 |

| 14 | 78.60 | 39.30 | 100 | I 6, I 16T80-0.8/1600-14 | 3210 | 3605 | |

| 18 | 82.00 | 63.50 | 150 | I 6, I 16T80-1.0/1600-18 | 3580 | 4205 | |

| 100 | 10 | 101.40 | 28.10 | 100 | I 6, I 16T100-0.8/1600-10 | 3905 | 4330 |

| 14 | 98.80 | 49.40 | 125 | I 6, I 16T100-1.0/1600-14 | 4040 | 4585 | |

| 18 | 98.80 | 76.30 | 150 | I 6, I 16T100-1.2/1600-18 | 4200 | 4930 | |

| 120 | 10 | 115.50 | 4250 | 125 | I 6, I 16T120-1.2/1400-10 | 4350 | 4980 |

| 14 | 119.00 | 59.40 | 125 | I 6, I 16T120-1.2/1 600-14 | 4770 | 5440 | |

| 150 | 14 | 149.15 | 59.40 | 125 | I 6, I 16T150-1.2/1800-14 | 6431 | 7396 |

| 18 | 149.86 | 76.30 | 150 | I 6, I 16T150-1.2/2000-18 | 6643 | 7639 | |

| 20 | 147.60 | 83.81 | 150 | I 6, I 16T150-1.2/2050-20 | 6769 | 7784 | |