Stainless steel reactor

Reactors are widely used in fields such as petroleum, chemical, rubber, pesticides, dyes, pharmaceuticals, and food. They are pressure vessels used to complete processes such as vulcanization, nitration, hydrogenation, alkylation, polymerization, and condensation, such as reactors, reaction pots, decomposition pots, polymerization pots, etc; Materials generally include carbon manganese steel, stainless steel, zirconium, nickel based (Hastelloy, Monel, Inconel) alloys, and other composite materials.

Main technical parameters of steam heated stainless steel reaction pot

| Specifications | Inner cyinder diameter ΦMM | Inner cyinder diameter ΦMM | Electric motor power KW | Gearbox model | Mixing speed r.p.m |

|---|---|---|---|---|---|

| 30 | 400 | 500 | 0.6~1.1 | M2 | 60~85 |

| 50 | 500 | 600 | 0.6~1.1 | M3 | 60~85 |

| 100 | 550 | 650 | 1.1~1.5 | M4 | 60~85 |

| 150 | 600 | 700 | 2.2 | M6 | 60~85 |

| 200 | 650 | 750 | 2.2 | M6 | 60~85 |

| 300 | 800 | 900 | 2.2 | M6 | 60~85 |

| 500 | 900 | 1000 | 2.2 | M6 | 60~85 |

| 800 | 1100 | 1200 | 4 | M8 | 60~85 |

| 1000 | 1200 | 1300 | 4 | M8 | 60~85 |

| 1500 | 1300 | 1400 | 4 | M8 | 60~85 |

| 2000 | 1400 | 1500 | 4 | M8 | 60~85 |

| 2500 | 1400 | 1500 | 7.5 | BLB7.5-4-13 | 90 |

| 3000 | 1400 | 1500 | 7.5 | BLB7.5-4-13 | 90 |

| 3500 | 1400 | 1500 | 7.5 | BLB7.5-4-13 | 90 |

| 4000 | 1500 | 1600 | 7.5 | BLB7.5-4-13 | 63 |

| 5000 | 1600 | 1700 | 7.5 | BLB7.5-4-13 | 63 |

| 6000 | 1800 | 1900 | 15 | BLB7.5-4-13 | 100 |

| 8000 | 2000 | 2100 | 15 | BLB7.5-4-13 | 100 |

| 32000 | 3000 | 3200 | 37 | BLB450-11-45 | 50~100 |

Main technical parameters of electric heating stainless steel reaction pot

| Reactor specifications (L) | Electric heating power(KW) | Inner pot size (mm) | Clamp size (mm) | Oil jacket capacity(L) | Outer diameter size (mm) | Gearbox model | Motor power | Mixing speed (RPM) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|

| 30L | 3 x 2KW | Φ350 | Φ550 | 50 | Φ718x1900 | M2 | 0.55KW | 85 | 250 |

| 50L | 3 x 2KW | Φ400 | Φ600 | 75 | Φ824x2015 | M3 | 0.75KW | 85 | 270 |

| 100L | 6 x 2KW | Φ500 | Φ700 | 130 | Φ1004x2120 | M4 | 1.1KW | 85 | 340 |

| 200L | 6 x 2KW | Φ600 | Φ800 | 150 | Φ1104x2120 | M4 | 1.5KW | 85 | 700 |

| 300L | 6 x 3KW | Φ700 | Φ900 | 180 | Φ1208x2495 | M4 | 2.2KW | 85 | 700 |

| 500L | 9 x 4KW | Φ900 | Φ1100 | 280 | Φ1468x2695 | M6 | 2.2KW | 85 | 930 |

| 1000L | 12 x 4KW | Φ1200 | Φ1400 | 420 | Φ1896x3110 | M8 | 4.0KW | 85 | 1610 |

| 2000L | 15 x 4KW | Φ1400 | Φ1600 | 740 | Φ2005x3500 | M8 | 5.5KW | 85 | 2010 |

| 3000L | 15 x 4KW | Φ1600 | Φ1800 | 1300 | Φ2165x3600 | M8 | 7.5KW | 85 | 2590 |

| 4000L | 15 x 4KW | Φ1700 | Φ1900 | 1500 | Φ2265x3800 | M10 | 11KW | 85 | 3160 |

| 5000L | 18 x 5KW | Φ1800 | Φ2000 | 1800 | Φ2370x4000 | M10 | 15KW | 85 | 4100 |

| 6000L | Φ2000 | Φ2200 | 1900 | Φ2570x4700 | M10 | 15KW | 85 | 4500 | |

| 8000L | Φ2200 | Φ2400 | 2100 | Φ2900x4700 | M12 | 18.5KW | 85 | 6170 | |

| 10000L | Φ2400 | Φ2600 | 2400 | Φ3150x4900 | M12 | 18.5KW | 85 | 7050 |

PRODUCT DISPLAY

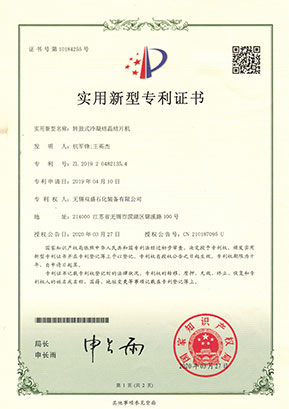

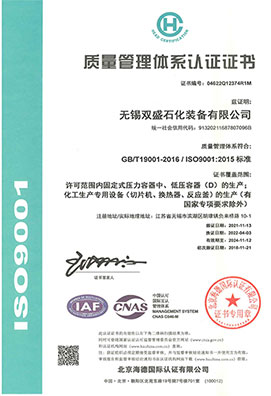

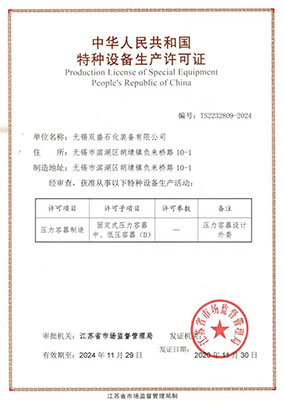

CERTIFICATIONS

WHY CHOOSE US

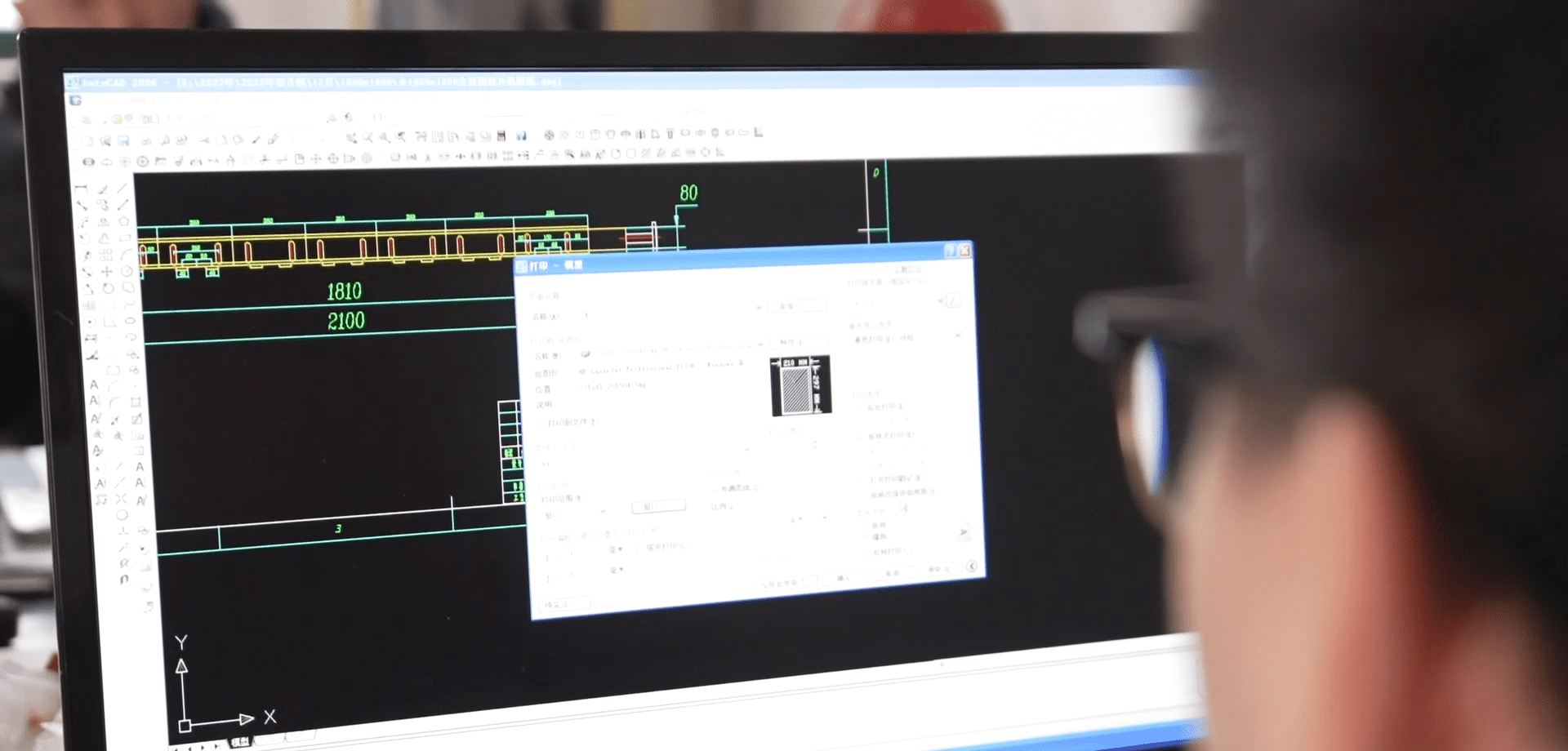

Effective technical support and high quality products

we have heavily invested in technological innovation. Our team includes 19 technical designers, and we use SW6-98 calculation software to ensure standardized and regulated design and drawing processes.

As a certified manufacturer authorized by the Quality and Technical Supervision Bureau and Space Ministry Of China, we are qualified to produce Class I and II pressure vessels and chemical equipment. In 2012, we obtained the Class I and II (A2 grade) Pressure Vessel Manufacturing License (No. TS2210F48-2016) issued by the General Administration of Quality Supervision, Inspection and Quarantine. Additionally, we earned the 2000 edition Quality System Certification from the China Classification Society in 2009.

Our Shuangsheng Strength

Originally founded in 1991 as Wuxi Xuelang Chemical Heat Exchange Equipment Factory, the company expanded and rebranded as Wuxi Shuangsheng Petrochemical Equipment Co., Ltd. in 2009. We occupy a 30,000-square-metre facility, with 3,000 square metres dedicated to office space, and have a registered capital of CNY 28 million . Our team consists of over 50 employees.

We specialize in the production of various pressure vessels, including slicers, flakers, drum flakers, condenser crystallizing slicers, and spiral plate heat exchangers. Each year, we supply customers with more than 200 flaking machines and over 20,000 square metres of heat exchange equipment, along with hundreds of custom non-standard and reaction equipment units.

strong customized ability and relia lbe solutions

Besides the rotary drum flaking machine and rotary drum cooling machine, we also produce pilot plants which offers you the investigation of the feasibility of a desired process, this approach contributes significant cost savings in the year of operation to come.

PARTNERS

TECHNOL OGICAL INNOVATION INTEGRITY AND PRAGMATISM

By accumulating more and more experiences and technical research, we have been striving for innovation of process solutions and has an excellent capabilities to solve all your required technical problems. We will keep making new contributions to the product performance and quality.

With wide range of our product applications, we are ready to be your reliable partners in the future.Our company is built on the values of “integrity, dedication, and a people-first approach”, with a commitment to “creating value for our customers”. We warmly welcome partners from all sectors, both new and old, to discuss cooperation opportunities and work together toward a prosperous future.

Contact us:Daisy

Cellphone:+86 13771159885

Whatsapp/Wechat:+86 13771159885

Email:sales@wxsssh. com

Address:No. 10, Negative Laiqiao Road, Hudai Industrial Park, Binhu District, Wuxi City in China